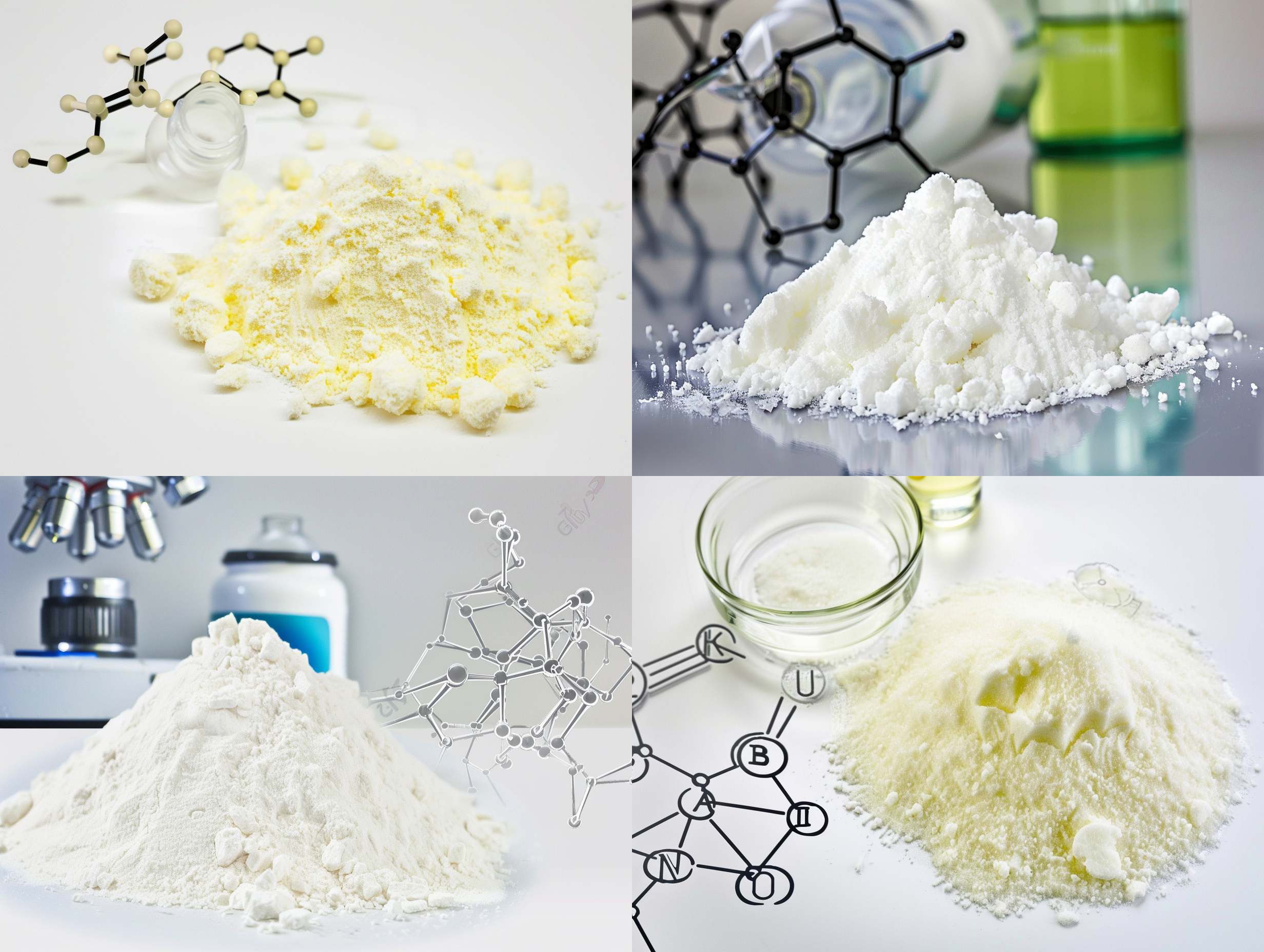

In recent years, the rubber industry has witnessed a notable shift towards the adoption of high-purity vulcanizing agents. These agents are essential for improving the resilience, durability, and performance of rubber products. As market demands evolve, understanding the implications of these changes is vital for industry stakeholders.

The increasing requirements for superior quality in rubber products have led manufacturers to seek high-purity alternatives. High-purity vulcanizing agents not only enhance product performance but also reduce the risk of defects and failures, thereby catering to industries such as automotive, aerospace, and consumer goods.

The incorporation of high-purity vulcanizing agents is reshaping production processes, enhancing efficiency, and leading to cost savings in the long run. This trend not only meets the technical specifications but also aligns with the sustainability goals of the industry.

As we look to the future, the demand for high-purity vulcanizing agents will continue to rise, making it imperative for companies to stay ahead of market dynamics. By leveraging these advanced agents, manufacturers can secure a competitive edge and cater to the increasing expectations of their customers.